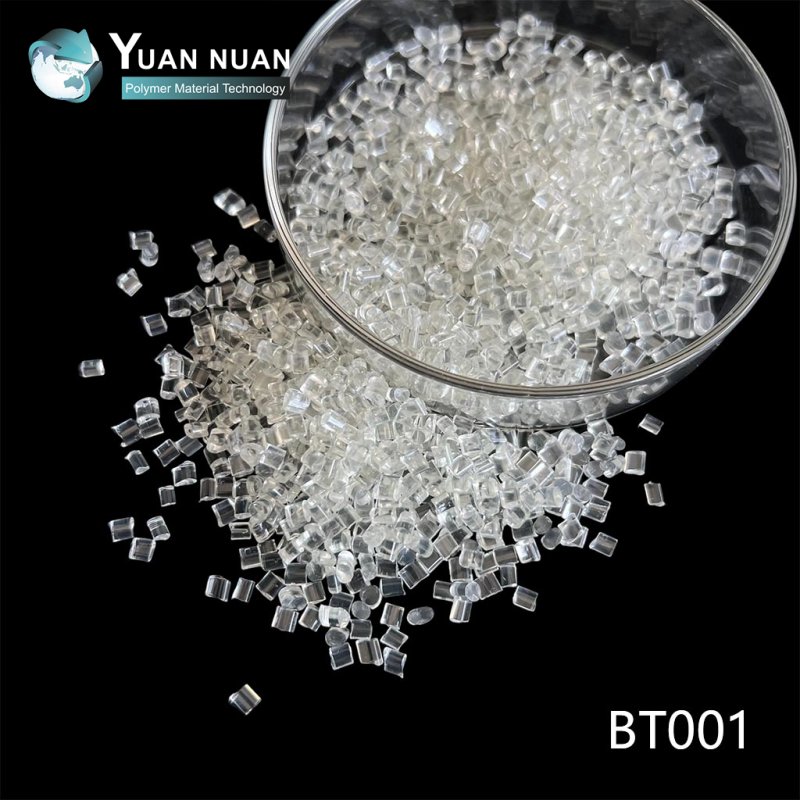

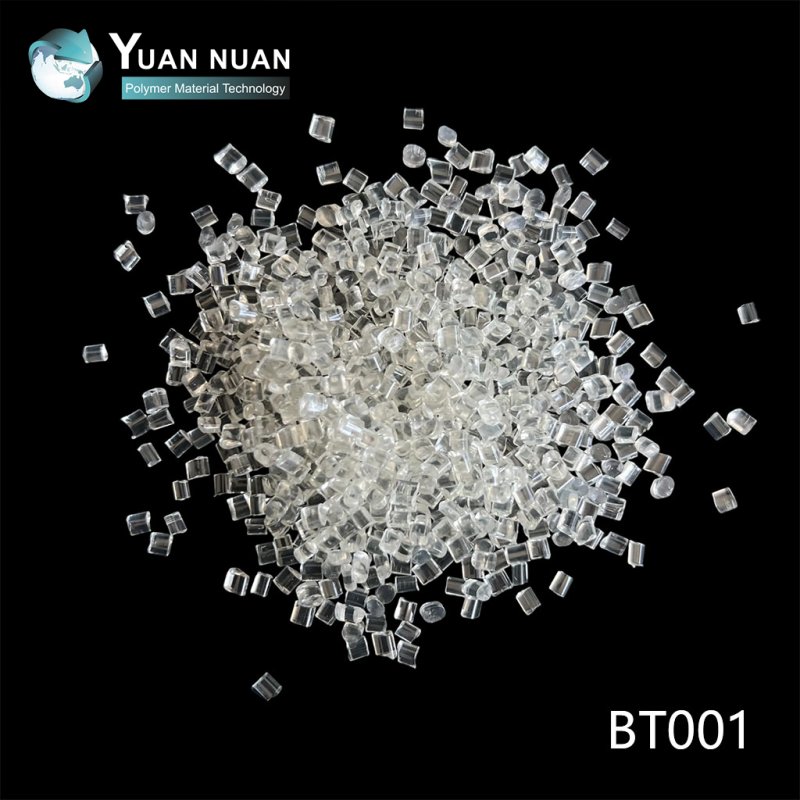

BT001

| Product Name | BT001 |

| Product Type | AS-g-GMA |

| Appearance | Transparent pale yellow granules |

| Density (g/cm³) | 1.07±0.01 |

| Melting Point (℃) | 180 |

| [1] MFR (g/10min) | / |

| [1] Grafting Ratio | High |

| Dosage | 3-5% |

| Packaging | 25KG Bag |

| Delivery Time | 10 Working Days |

Disclaimer: Data provided is based on internal laboratory testing and serves as a reference for material selection. It shall not be construed as product specifications.

Testing Limitations: Due to limited data and experience, the above performance metrics are for reference only.

Notes:

[1] Grafting ratio classification:

Ultra high: >1.8% | Very High: 1.0–1.2% | High: 0.8–1.0% | Moderately high: 0.5–0.8% | Medium: ≈0.5%.

Introduction

BT001 is a functional compatibilizer based on AS resin grafted with maleic anhydride (AS-g-MAH). Its reactive anhydride groups enhance interfacial bonding in styrene-containing systems (e.g., ABS, AS) through polarity matching. Designed with low odor and low dosage, it efficiently modifies fiber-reinforced and styrenic alloy systems.

application

1、Styrenic Composites: e.g., ABS/GF, AS/GF – improves fiber-matrix adhesion;

2、Alloy Interface Optimization: e.g., ABS/PA, AS/PA – enhances low-temperature impact resistance;

3、Eco-Friendly Export Products: Low volatility meets stringent environmental standards.

related parameters

| Product Name | BT001 |

| Product Type | AS-g-GMA |

| Appearance | Transparent pale yellow granules |

| Density (g/cm³) | 1.07±0.01 |

| Melting Point (℃) | 180 |

| [1] MFR (g/10min) | / |

| [1] Grafting Ratio | High |

| Dosage | 3-5% |

| Packaging | 25KG Bag |

| Delivery Time | 10 Working Days |

Disclaimer: Data provided is based on internal laboratory testing and serves as a reference for material selection. It shall not be construed as product specifications.

Testing Limitations: Due to limited data and experience, the above performance metrics are for reference only.

Notes:

[1] Grafting ratio classification:

Ultra high: >1.8% | Very High: 1.0–1.2% | High: 0.8–1.0% | Moderately high: 0.5–0.8% | Medium: ≈0.5%.

Packaging and Storage

25 KG kraft paper bags with inner plastic liners.

Store in dry, ventilated, cool conditions (≤25°C). Avoid humidity and direct sunlight. Use promptly after opening.